dirknerkle

Supporting Member

You may be able to physically cut the matrix in half, but whether it will run again after that is another matter...

The connectors appear to be male/female. Most of us wire male on the input. Using the "end connector" will not work (data will be backwards). You will want to pick up some pigtails that match the existing connector and solder them in.Would you cut it in the middle to control the upper 1000 pixels with the existing upper connector and control the lower 1000 pixels with the lower existing connector? Then I don't have to solder connectors on, just cut the cable.

That's exactly my worry and why I was asking for input. These matrixes are expensive... I would hate to destroy them. Looking at the details, it seems to me that the "main line" on one of the shorter edges is a relatively thick cable consisting of 3 conductors. So must be power and data. From there, there seem to be 4 conductor pebble/seed strings, two power, one data, one backup data. I can't drive the whole 2000 LEDs from one F48 port. At the minimum I need to use 2 ports, 1000 LEDs on each port (500 if I want 40fps, if my F48 v1.04 even supports 40fps). So the idea was, I cut that "main line" to separate the 2000 LEDs into 2x 1000 LEDs. Then I use the upper and lower connector to drive each of the two sections with one F48 differential port, each.You may be able to physically cut the matrix in half, but whether it will run again after that is another matter...

ws2811/ws2812 don't enumerate themselves. They simply take 24 bits of data and pass the rest along. They have no idea where they are in the string or if anything is in front of them or behind them.But thinking about this, how does each pebble/seed string know who it is? Pixels can enumerate themselves when they are all in one long string.

Well, enumerating was wrong. But as data comes down a string, a pixel takes out the value and keeps it for itself. Then it sends on the rest of the data coming in. So the first pixel takes the first 24 bits (for RGB), the second pixel takes the second 24 bits coming down the string, etc. So it's kind of enumerating.ws2811/ws2812 don't enumerate themselves. They simply take 24 bits of data and pass the rest along. They have no idea where they are in the string or if anything is in front of them or behind them.

Your design change is a god decision.

Well, I saw the 4 wires and was hoping that's a backup channel as with the WS2815. It appears that's not the case. I do have a couple of soldering irons (desk and portable), "helping hands" for doing stuff on the desk, tinner, water sealing 3:1 shrink wrap, etc. I am no expert by any means with this stuff, though. Our son is probably doing better with soldering than me."So I would expect that if one LED breaks, the rest of the matrix will be down"

This happens to 100% of the pixel based props. You WILL need to learn to replace pixels and you WILL need spare pixels around and you WILL need to learn to solder.

Hmm, maybe my problem is that I didn't use any of the attachments to direct the heat. While I used the heat gun on low heat and did further adjustment by changing distance, I just used the round opening (no attachment). Maybe not using any attachment is the problem. I have to give this another try...Yes those. And a heatgun with a directed nozzel and temp control. It took a lot of practice to get it right, but it was worth it.

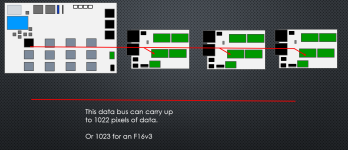

I figured out the part where you don't daisy chain the differential boards. Basically, each port of the 4 differential controllers that are connected to bank one (red box in your figure) can support the number of pixels/nodes (3x channels) for whatever you set. Lets say x pixels. Then each of the 16 ports (4 differential controllers and 4 controllers per bank) is set to y pixels and for the last bank, you have 16x 1024-x-y pixels. So at the end you have 16x (x+y+1024-x-y)=16x 1024 pixels = 16384 pixels.Yes.

View attachment 47654View attachment 47655

View attachment 47656View attachment 47657

That's the F48 version slideshow, related to this video I did on the F16v3:

Ironically I made the F48 slides up before the F16 and never recorded it for Youtube.... wasted time whoops.

There is a way to get past the 'limit' of 1024 on the Falcons. But I really don't want you to do that.

Yes. Only 4 differential receivers (all on one bank, not chained) is need to get the the advertised 16,384 pixels (almost, technically 16,532).Duh about the daisy-chaining. I should have read the user manual for the smart differential board to the end. In my mind, each of the daisy chained smart receiver is taking up one port on the F48 controller. They are just not physically connected to a port (because they are daisy chained) but then those ports would basically be turned off on the F48. But that's completely wrong. You can still use all 12 ports on the F48. All you do is distributing(!!!) the number of pixels/nodes you would have with a single smart differential receiver over 2 or 3 smart receivers. It kind of makes sense as that way the data rate and the overall design of the F48 doesn't change. It really limits the usefulness of what I though daisy chaining can do. And I created a box with a PSU and two differential receivers in it. That makes no sense anymore now, or at least I can't think of why one/I would do that as you should be able to emulate this with virtual strings. Except maybe you can reduce power injection as now you have 8 outputs instead of just 4, i.e. you can make shorter strings, if the design allows it.