We have a 2 car garage (just one door) that is probably 16' wide and 8' tall. I am thinking of building an LED curtain for it. The door is only about 20' away from the sidewalk. So I think I would have to place the LEDs somewhat close. Most pixels strings have pixels 4" apart. Would this still give a good effect where you can recognize pattern well from 20' away?

Assuming a distance of 4", there are 16*3=48 pixels for the 16' and 8*3=24 pixels in 8'. So that's a total of 1152 pixels. WS2811 pixels are at least $0.25/pixel. But I would need individually addressable pixels, e.g. WS1812(B). They seem kind of hard to find and probably more like $0.4/pixel. So that would be 1152*$0.4 = $460 just for the pixels, assuming you can find individual addressable pixels for $0.4/pixel.

There are WS2812B LED strips with 30 LEDs/m and 5m for about $20 for waterproof strips. So that's about $20 / 150LEDs = $0.14/LED. That's about 1/3 or a pixel but you end up with a lot more pixels, i.e. 3 pixels for every 4" instead of 1 pixel every 4". So now for 8' you have 8' / (3.28'/m) * 30 LED/m = 73 LEDs. So 74 LEDs vs the 24 pixels. Let's assume we still keep the 4" distance in the horizontal, that would still mean 48 strips to cover the 16'. So now we are at 48 strips with each strip 73 LEDs (realistically, you cut the 150 strip in 2) and you end up with 48*75 LEDs = 3600 LEDs. Each is $0.14 so a total of $504. So about 10% more but twice the density in the vertical.

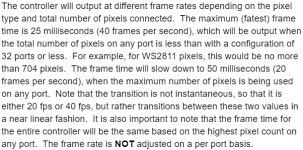

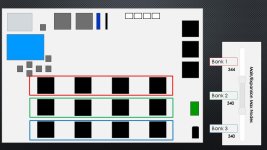

I think in xLight you can take care of the different densities in the vertical and horizontal. What about controllers? How well will LED strips compare to pixels? I don't plan to put them into some kind of PVC piping. I don't have the space to store this. I am thinking of just having some bar on top, then some kind of bar at the bottom to pull the strings straight. Has anybody done anything like that?

Assuming a distance of 4", there are 16*3=48 pixels for the 16' and 8*3=24 pixels in 8'. So that's a total of 1152 pixels. WS2811 pixels are at least $0.25/pixel. But I would need individually addressable pixels, e.g. WS1812(B). They seem kind of hard to find and probably more like $0.4/pixel. So that would be 1152*$0.4 = $460 just for the pixels, assuming you can find individual addressable pixels for $0.4/pixel.

There are WS2812B LED strips with 30 LEDs/m and 5m for about $20 for waterproof strips. So that's about $20 / 150LEDs = $0.14/LED. That's about 1/3 or a pixel but you end up with a lot more pixels, i.e. 3 pixels for every 4" instead of 1 pixel every 4". So now for 8' you have 8' / (3.28'/m) * 30 LED/m = 73 LEDs. So 74 LEDs vs the 24 pixels. Let's assume we still keep the 4" distance in the horizontal, that would still mean 48 strips to cover the 16'. So now we are at 48 strips with each strip 73 LEDs (realistically, you cut the 150 strip in 2) and you end up with 48*75 LEDs = 3600 LEDs. Each is $0.14 so a total of $504. So about 10% more but twice the density in the vertical.

I think in xLight you can take care of the different densities in the vertical and horizontal. What about controllers? How well will LED strips compare to pixels? I don't plan to put them into some kind of PVC piping. I don't have the space to store this. I am thinking of just having some bar on top, then some kind of bar at the bottom to pull the strings straight. Has anybody done anything like that?